A well designed bottom rolling door system will remain operable in conditions that will stop other designs in their tracks. High winds, heavy snow and power outages that disable other designs are easily overcome by a high quality bottom rolling door.

Features

A high quality bottom rolling hangar door is the most rugged and reliable door there is, period.

Design Options:

- Flexible and easily customizable to allow virtually unlimited design options.

- Unlimited size, highest insulation capability, truck doors, pilot access doors, air plenum or filter banks, tail doors, liner panels, glazing, tail apertures, unlimited cladding options.

- Manually operated doors as opposed to electrically motor operated to reduce complexity and expense.

- Electric motor operators can be designed and built into your system to meet your specific needs.

Other Benefits:

- The lowest life cycle cost of any design.

- Flexibility of the panels' operation. The panels don't require any power to move them.

- Long service life components that require very little maintenance.

Bottom Rolling Door Types

All Moving Panels

One configuration of bottom rolling hangar doors is referred to as All Moving due to the fact that the panels are not restricted which direction they slide and are individually operated. This configuration of bottom rolling hangar door is typically chosen for applications needing maximum flexibility in larger hangars allowing multiple aircraft without using stacking pockets (see “Single Stacking Panels” below). Simply move all panels to the side of the hangar which doesn’t need to be open. In Northern climates, all moving configurations may require heated rails.

All Moving bottom rolling hangar doors can be fitted with a large variety of options designed to fulfill your needs. The doors may be operated manually or by electric motor. Manual operation is popular in this configuration due to the fact that the operator does not have to push all panels at once and can push one at a time which is almost effortless. If the panel is chosen to be electrically motor operated, the price tends to be a bit more expensive than the other configurations. Each panel is fitted with a motor and control panel and power is fed to each panel through trolley duct feed system along each rail. Other options are recommended with that option such as safety edges along both edges and limit switches to prevent collisions at each panel.

Single Stacking Panels

Single stacking bottom rolling hangar doors install on virtually any type of building, saving money and space. Single Stack doors have been specified for aircraft hangars, tee hangars, industrial and agricultural buildings and even… floating barges! When manually operated, these doors slide similar to all moving doors except that they close in one direction and they open in the opposite. They "stack" in one end which is recommended to be a wing wall or section built out of the building to store the doors while utilizing the full width of the hangar for the opening. In cases where the space to either side of the opening is not available then a wall is required to stack the doors behind while the door is open.

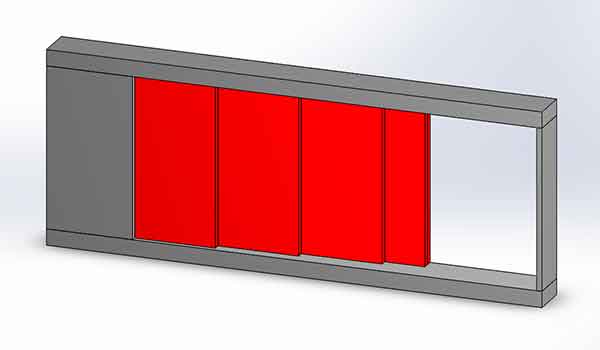

Bi-Parting Panels

The last configuration of bottom rolling hangar door is a very elegant design if space required is no issue. This configuration of door meets in the middle and half the panels open to one side while the other half open to the other side. This design requires an even number of panels and may be manually operated but is usually electrically motor operated which means two motors are required; one for one half and one for the opposite half. This configuration has the same stacking requirements as a single stack configuration but for both sides. Be prepared to give up some room for these doors. This configuration does work really well to decrease the amount of room required into and out of the building. An example is that instead of running 4 panels on their own separate rails they can now be located on 2 separate rails and save the space that would be used by the other two rails. This is a game changer for some hangar owners.

Northern Rail Layout

Named partly because of its common geographical location, the Northern states. The rails are protected from ice and snow in cold weather by a pocket built into the building that keeps the rails protected. Rails are also protected by the physical orientation of the stack of panels leaving no exposed rails in the closed position.

The rail layout only affects the location of the rails in respect to the building, a Northern layout can be chosen for Biparting and Single Stack configurations.

Southern Rail Layout

Named partly because of its common geographical location, the Southern states. The rails stay outside of the buildings’ walls because snow and ice are not as concerning in the south and the face that the panels are on the exterior of the building allow more space to be utilized for the customer.

Solar Powered Electrically Operated Doors

Electrically operated bottom rolling doors present some unique power supply and control issues in some configurations. 21st has overcome these issues with our “Solar Option”. Solar panels are properly sized and installed into the outside skin or cladding of the door. The power from the panels charge a battery bank which is built into the door. The battery bank provides an uninterruptible power source to the motor drive which will open or close the door. The door will function normally even when the power is off to everything else in the building! This Solar Option is available on all the different 21st door models.

Service and Repair

Alamo Door Systems services and repairs all makes and models of Bottom Rolling Hangar Doors.